If China Invades Taiwan Tomorrow, Your Next iPhone Won’t Exist.

How a 50-person startup is betting they can break the TSMC-ASML duopoly with particle accelerators and X-rays

Sounds exaggerated? It’s not.

Today, 90% of the world’s most advanced chips are manufactured by a single company: TSMC, in Taiwan. And the machines that make those chips possible? Only one company in the world can build them: ASML in the Netherlands.

This duopoly seemed impossible to break. And when you understand the complexity of these machines, it seems like science fiction that anything else could work.

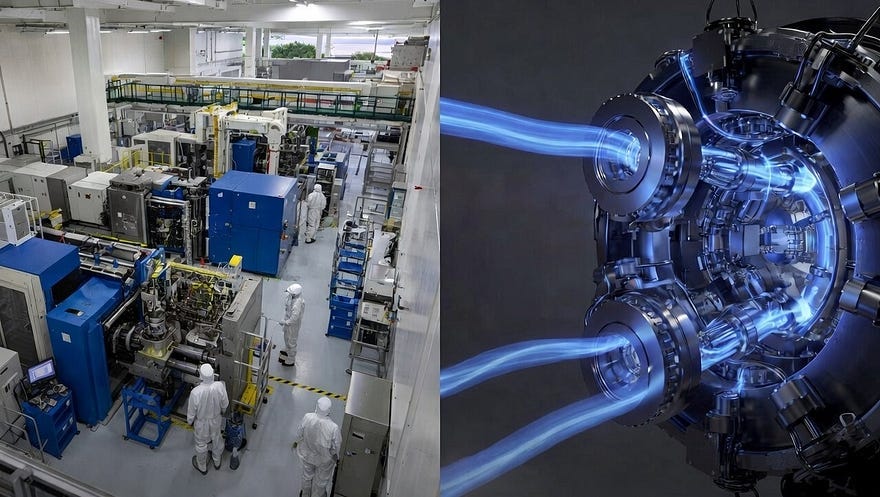

But recently, a 50-person startup emerged from the shadows with a promise that’s making the industry tremble. A completely new machine capable of printing chips at the sub-nanometer scale in a single exposure, for a tenth of the cost.

And the most fascinating part? They don’t want to sell this machine. They want to build entirely new factories around it.

This startup is called Substrate. And what you’re about to discover in the next few minutes could represent the biggest upheaval in the semiconductor industry since the invention of the transistor.

I’m measuring my words carefully here.

Why Making Advanced Chips Became an Economic Nightmare

To understand why this announcement is making so much noise, you first need to grasp how nightmarish advanced chip manufacturing has become economical.

Lithography, the step where circuits are etched onto silicon, represents the absolute bottleneck of the entire industry. ASML’s EUV machines, these bus-sized monsters, now cost $380 million each for the most advanced versions.

Intel just finished acceptance testing of its first machine at its Oregon facility in early January 2026. Samsung also received deliveries last week. TSMC launched construction of yet another new factory in Taiwan for the 1.4nm process. $48.5 billion is the price tag for this sole factory.

Ponder that lunacy. There is only one factory. That’s a substantial sum, exceeding the GDP of several countries. Exclusively for one factory.

Meanwhile, China just accomplished what everyone thought was impossible. A group of researchers in Shenzhen successfully built and tested their prototype chip etching machine.

But how? Because I just told you, this is science fiction technology.

By recruiting former ASML engineers. The engineers who built these machines themselves.

Some analysts call this China’s Manhattan moment, a reference to the secret American project that created the atomic bomb. The technological race is accelerating, and costs are exploding on both sides.

The Physics Problem Nobody Could Solve

Why is building this machine so expensive? The problem is physics itself.

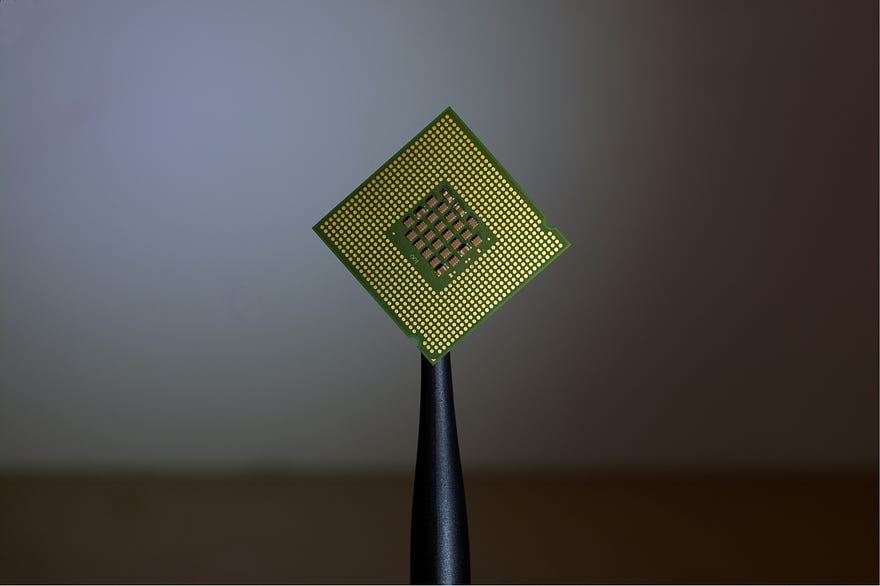

To etch increasingly small circuits on a chip, you use light. And the finer the light, the smaller you can etch. It’s like trying to draw tiny details. You need a very fine pencil, and the finer it is, the smaller the details will be.

Today, the most advanced machines use what’s called EUV, extreme ultraviolet light. Light with a wavelength of 13.5 nanometers. To give you a scale, a human hair is about 80,000 nanometers. We’re talking about light 6,000 times finer than a hair.

It’s extraordinarily small. But it’s no longer enough.

So the industry found a trick. Instead of etching the circuit in one go, you etch it in multiple passes. A bit like if you had to print a high-definition photo, but your printer wasn’t precise enough. So you print multiple layers on top of each other to get the final result.